Modular Home Construction’s Hidden Structural Superiorities

At a glance, modular home construction looks exactly like traditional stick-built structures. Let’s take a deeper look into a number of the critical differences that make modular construction an overall superior product.

Lagged Corner Framing

To those of you who don’t understand the difference between nailing and lag bolting, we need to demonstrate that for you. Our modular home’s frames are lagged together which makes them structurally incomparably strong vs our stick-built competitors.

Walls Secured with Screws & Nails

Walls are set in place first with nails, then with screws for extra tight framing. Most traditional builders skip the screws as it adds time and expense. We never skip the screws.

HVAC Boots Sealed to Floor

Helps eliminate air leakage for cooler summers and warmer winters

Insulated Solid Headers with 1" Foam

Provides a thermal break to prevent unwanted transfer of heat

Mud Blocks on Back of Drywall Seams

Smart use of excess material eliminates unnecessary waste and makes a stronger drywall seam

Backer Board for Shelf & Mirror Attachment

Provides a large area to securely fasten closet shelving and bathroom mirrors

Blocking for Kitchen & Bath Electrical Boxes

Provides extra support for these high-use areas

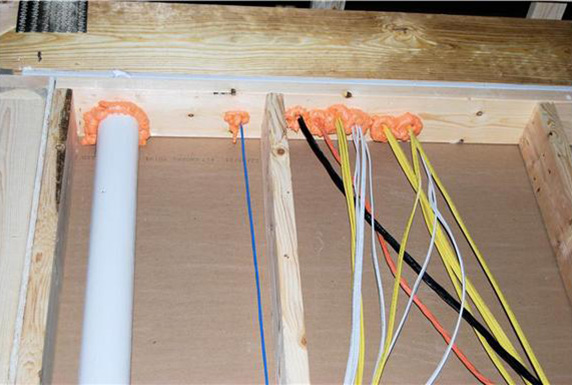

Fire Stop at All Framing Penetrations

It's not just for code... it's also a good idea. And makes your home more airtight.

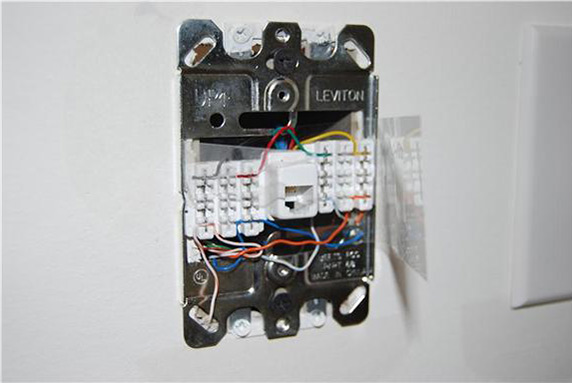

Cat-5 Phone Wire

You could actually create a computer network for your whole house with our standard phone wire

Gaskets on Exterior Wall Electrical Boxes

Helps to insulate and eliminate drafts

Concealed Fasteners for Kitchen Cabinets

Provides a clean, finished look for your new cabinets

To learn more about the modular building system, contact Tidewater Custom Modular Homes.